- HOME

- Catalog

- Products that use our tools

-

In recent years, we have expanded the size variation of our machinable tools, and our Hob Cutter is used by clients who manufacture measuring instruments to small motors, in a wide range of fields. We also produce single cutters and metal saws to meet the requirements of our clients.

※Click here for full download of catalog

Details

-

-

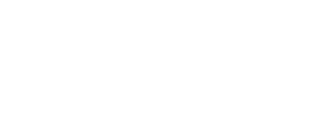

Hob cutter

-

Cycloid hob cutter

-

Minimum actual hob cutter

-

Maximum hob size that can be considered for processing

-

-

-

-

Raw carbide material

-

Inside diameter grinding/End face grinding

-

Hub grinding

-

Tooth groove grinding/Tooth profile grinding

-

-

-

-

C chamfer metal saw

-

Formed cutter

-

-

-

-

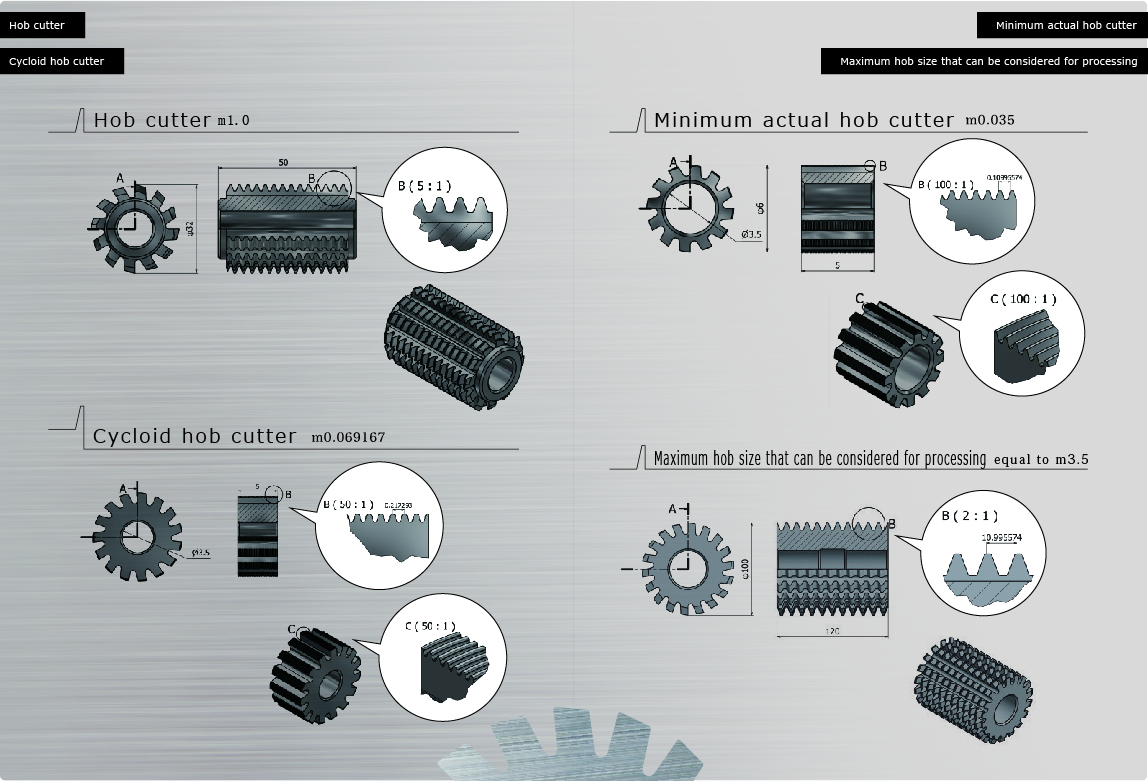

Formed cutter

-

7 blades cutter(straight bevel)

-

1 blade/2 blades/3 blades cutter

-

-

-

-

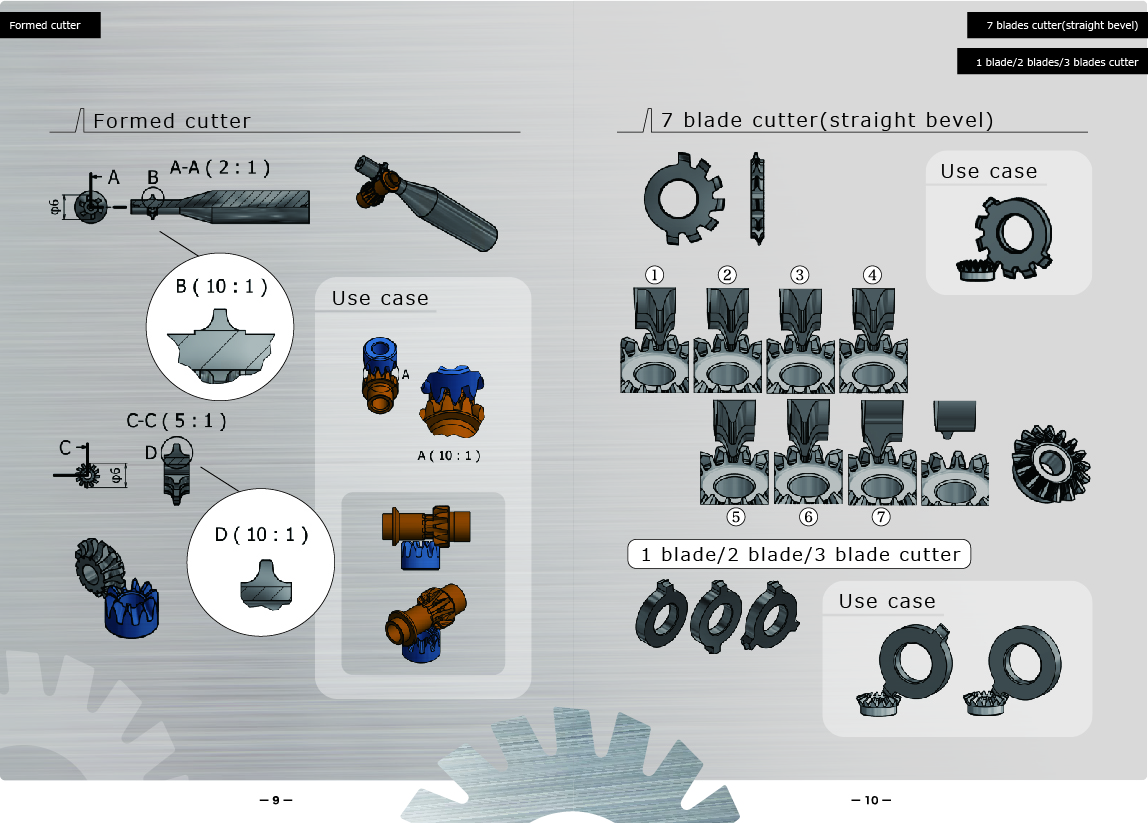

Countermeasure form tooth profile measurement result

-

Size of carbide material in stock

-

-

-

-

Catalog values of carbide material

-

Recommended machining conditions for carbide tools

-

-

Precautions for using carbide tools

Carbide tools have sharp blades. Please make sure to wear protective gloves, protective glasses, protective mask and machine cover etc. when using carbide tools, as there is a risk of the tools breaking in the following cases.

- ■Due to excessive impact or severe abrasion, tools can be damaged, or break and scatter, which may cause injuries.

- ■When the installation of tools and workpieces are loose during use, tools can be damaged, or break and scatter, which may cause injuries.

- ■During the installation, if the rotation balance is bad, tools can be damaged, or break and scatter due to swing or vibration, which may cause injuries.

- ■If the processing is conducted outside of the recommended machining conditions and guidelines, tools can be damaged, or break and scatter, which may cause injuries.

- ■There is a danger of heat being generated while in use. This may result in fire hazards due to sparks and tools breakage that occur during use.

- ■There is a danger of burns due to high temperatures of tools, workpieces and chips immediately after processing.

- ■Since the specific gravity of carbide material is large, please handle the material carefully while carrying.

- ■Carbide material can be damaged and may crack if impacted,. Please be careful during use.

- ■Carbide material can lose strength due to corrosion. As moisture in the air, cutting fluids, and cutting oils may be causes for corrosion, please take extra care in before and during storage.

- ■Since dust produced during grinding of carbide material may be harmful if inhaled, please install an exhaust device and use a protective mask.

- (Please refer to the Material Safety Data sheet issued by our company for detailed information.)

- ■Please confirm that there is no damage or cracks when grinding carbide tools.

※Click here for full download of catalog