- HOME

- Production flow

Efforts to improve products accuracy

Our company utilizes years of experience in grinding technology, and constantly aims to achieve the highest accuracy possibly in order to satisfy customers and meet their requirements. In order to achieve high accuracy, we not only focus on production, but we start with fundamentals, such as the refinement of the infrastructure of our factory, making sure that the smallest details are managed properly from appropriate room temperature / humidity management, to a high level of security.

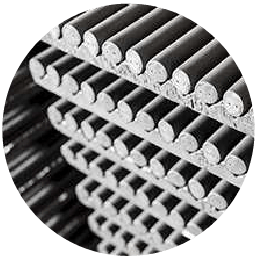

Carbide materials, the main material for our cutters, are produced and delivered according to the following process. As shown in the following image of ‘‘Molding process’’, the materials are produced in cylindrical shapes and with blade grooves before they are processed as cutters.

-

Production of raw material powder

-

-

Press molding / machining

-

-

Sintering

-

-

Molding process

The surface is ground step by step from the material, and the precision of each procedure is strictly maintained until completion.

▼The image of Inside diameter grinding

(STEP02)

▼The image of End face grinding

(STEP03)

After completion of tooth profile grinding, inspection is carried out on all details, and only the products that meet all criteria can be delivered to customers as our products. ※Regarding the products with coating, the final inspection will be after the coating process.

The hobs produced are sent to coating makers. They are then coated with professional processing equipment after thorough cleaning. Regarding the kind of coating and the thickness of coating, please contact us.

-

The image of before the coating process

-

-

The image of after the coating process

The images are provided by Onwardgiken Co., LTD.

URL:http://www.onwardgiken.jp/